Home » Sealing Products » Hydraulic and Pneumatic Seals

Hydraulic Seals | Pneumatic Seals

A well-designed hydraulic/pneumatic sealing system is critical for optimal performance in dynamic applications.

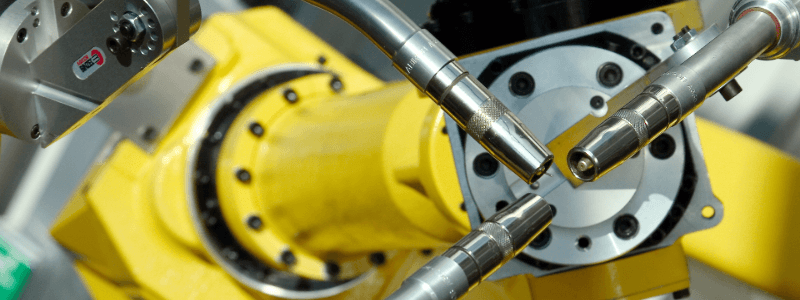

Dynamic Seals

Three-dimensional like the O-ring, dynamic seals for hydraulic and pneumatic applications are engineered with superior tolerances to provide tight closures involving moving parts.

Dynamic seals are more complex sealing devices that provide high-performance leak prevention in an endless variety of seal geometries. Typically, a hydraulic seal is a non-metallic ring or an assembly of rings that block or separate fluid during motion. Pneumatic seals are designed for cylinders and valves activated by air, generally at high speeds.

Hydraulic and pneumatic sealing environments require a wide array of dynamic seals and wipers. Despite the variety in both styles and geometries, these seals can be categorized as one of three types:

- Seals for reciprocating applications

- Seals for rotary applications

- Seals for oscillating applications

To prevent failures, important factors to be considered when selecting materials specifically for hydraulic and pneumatic applications are:

- Typical physical properties (based on ASTM, SAE, AMS or aerospace standards)

- Durometer – a measure of hardness based on the Shore A scale

- Modulus – a measure of extrusion resistance

- Ultimate Tensile Strength – a measure of wear resistance or toughness

- Ultimate Elongation – a measure of the breaking point when the cured material is fully stretched

- Resilience – a measure of the “rebound” of a material after being compressed

- Compression Set – a measure of a material to return to the original shape after compression

- Chemical compatibility

- Thermal capability

- Friction and wear resistance

- Storage, handling and installation criteria

Types of Dynamic Seals

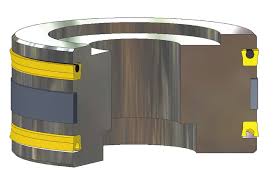

Garlock's Klozure series of bearing isolator seals

Bearing isolators separate the bearing from its environment. They provide two-way sealing, keeping the bearing well-lubricated while excluding contaminants and preventing leakage. The special labyrinth design of a bearing isolator consists of a two-part seal, including a stator fitted into a housing and a rotor attached to the shaft. The shaft and rotor revolve together.

Bearing isolators, or excluder seals, are typically made from various proprietary compounds compatible with hundreds of different chemicals, such as caustic acids and strong sulfides. Today’s bearing isolators exceed IEEE-841 for electric motors. They provide extended bearing life in pumps, gears and motors found in food processing plants, pulp and paper mills, mining operations and any environment where superior chemical resistance is required.

The V-ring is an automatic hydraulic and pneumatic seal designed for sealing rods, rams, pistons, and plungers. Also known as Vee Packing and Stack Packing, V-ring packings are lip-type seals and are gland sensitive.

Garlock Deep V-Ring CHEVRON® Packing

This type of dynamic seal consists of a male and female adapter with a series of V-shaped rings between them. Garlock’s Chevron® V-Ring utilizes a distinct hinge area to allow automatic reaction to pressure. Each separate lip of the packing assembly reacts to even minor pressure, automatically creating a tight fit to prevent contamination while retaining grease.

V-Ring packing is often used in automotive, off-road equipment, and power generation applications.

The Chevron® V-Ring Packing is available as:

- Fabric-reinforced, for general use and high pressure (in a variety of compound assemblies)

- PTFE, for low-friction and chemically aggressive media (in unfilled PTFE or carbon and graphite filled PTFE)

- Homogeneous rubber, for lower pressure and vacuum applications (in nitrile, silicone, butyl)

- A deep V-ring design

The Parker Polypak® is an all-purpose precision molded seal combining O-ring type energizers with conventional lip-type seal geometry to produce a seal capable of sealing in both low and high pressure environments.

As a squeeze-type seal, the Polypak® design provides high sealability at low pressure. As pressure increases, lip loading automatically increases to compensate, maintaining a positive, leak-free seal from hard vacuum to over 60,000 psi.

As a squeeze-type seal, the Polypak® design provides high sealability at low pressure. As pressure increases, lip loading automatically increases to compensate, maintaining a positive, leak-free seal from hard vacuum to over 60,000 psi.

Additional advantages of the spring-loaded Polypak® seal:

- Polypak’s® O-spring stabilizes the seal under extreme pressures, preventing seal lip distortion

- The O-spring design maintains lip loading on both the ID and OD of the seal interface at both low or high temperature extremes

- Polypak® seal can stretch or squeeze to handle undersize rods and oversize cylinder bores, as long as the seal cross-section is correct

- Wide range of materials insures proper combination for abrasion, extrusion, fluid compatibility and temperature resistance for long life and superior performance

Three Polypak® styles are available:

Three Polypak® styles are available:

Standard profile (SPP)

- Economical choice for stand-alone rod or piston seal

- Due to less squeeze force, it can be installed back-to-back in separate glands for bi-directional sealing

Deep profile (DPP)

- For use in either piston or rod applications as a stand-alone seal

Type B profile (BPP)

- O-ring energized lip seal with beveled lip design

- Can be a stand-alone seal or used with a buffer seal

A major cause of seal or component failure in hydraulic and pneumatic systems is damage from contaminants. Though not a seal itself, the rod wiper protects the seals and other internal components from excessive wear and other damage caused when such contaminants are introduced into the system.

A major cause of seal or component failure in hydraulic and pneumatic systems is damage from contaminants. Though not a seal itself, the rod wiper protects the seals and other internal components from excessive wear and other damage caused when such contaminants are introduced into the system.

Rod wipers use gentle motion to prevent contaminants from entering the cylinder as the piston rod retracts into the system. The primary lip of a typical rod wiper provides this wiping action during each stroke of the reciprocating cylinder rod. This removes abrasive foreign materials such as dust, dirt, mud, metal chips and other environmental debris from the exposed portion of the rod. At the same time, the wiper is able to maintain adequate lubrication on the rod so that it is protected from scoring.

Rod wipers are manufactured using a wide range of lip geometries and materials, most commonly elastomers, urethane and PTFE.

T-seals are used in a standard O-ring groove for industrial reciprocating glands that are designed to use zero, 1 or 2 back-up rings, but with additional advantages over O-rings.  The benefit of a T-Seal is that its compact design provides improved stability and extrusion resistance.

The benefit of a T-Seal is that its compact design provides improved stability and extrusion resistance.

- T-seals will not extrude through the gap between static and dynamic surfaces

- T-seals are more stable in the grooves, eliminating twisting or spiraling of the seal

- T-seals meet or exceed the O-ring's outstanding ability to seal at all pressures and temperatures

Developed to replace existing O-ring seals in long-lived hydraulic and pneumatic systems, the retrofit can be handled without re-machining or creating major revisions to existing equipment. T-seals can be installed as a either a rod seal or piston seal.

T-seals have a distinctive multi-functional cross-section, with back-up rings on the outside diameters of piston T-seals and on the inside diameters of rod T-seals.

Despite rapid strokes, lateral shock loads, pressure surges, and uneven wear or stretching, T-seals maintain zero extrusion gaps. In the free state, back-up rings appear quite loose on their seal element. This slack is taken up during installation, however, since the interference fit of the seal in standard O-ring grooves either stretches (piston seals) or compresses (rod seals) the element to seat the backups.

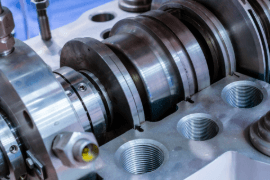

Rotary shaft seals, also known as oil seals or grease seals, are designed to keep lubricants from escaping between static and moving components, while preventing internal contamination from external sources. A rotary, or radial, shaft seal includes a flexible lip held against the shaft with the casing pressed into the static component to hold the seal in place.

Rotary shaft seals, also known as oil seals or grease seals, are designed to keep lubricants from escaping between static and moving components, while preventing internal contamination from external sources. A rotary, or radial, shaft seal includes a flexible lip held against the shaft with the casing pressed into the static component to hold the seal in place.

They can be manufactured using diverse combinations of elastomers, plastics, PTFE (Teflon®), springs and metals. Common elastomeric compounds include fluorocarbon (FKM), acrylate, nitrile (Buna-N), HNBR, and ethylene acrylic (AEM). In order to resist wear, the compound’s durometer (hardness) is typically 70 to 85 Shore A (between that of an automobile tire and an inline-skate wheel).

There are three basic designs:

- Spring-energized seal, which is essentially a U-cup seal utilizing a variety of profiles, spring types and materials

- Flexible-lip seal, which is a rotary shaft seal incorporating a deflected lip seal geometry for sealing corrosive and abrasive media

- Metal-cased rotary lip seal, which provides good chemical compatibility, wide temperature ranges and high pressure capabilities

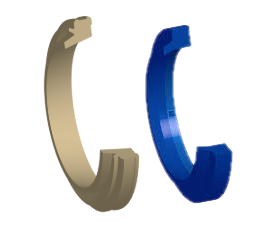

U-cups are the most compact and versatile of the many lip-type seals available. They are designed to be used as both a rod or radial shaft seal (inside diameter seal) or a piston seal (outside diameter seal). The distinctive “U”-shape energizes the two flared sealing lips as the application pressure rises. Because it does not roll or twist with the movement, the shaft or rod is not hindered and friction is reduced.

Depending upon the specific lip design and materials, a U-cup seal can be effective in low and medium pressure applications and can accommodate worn or out-of-round service environments.

Depending upon the specific lip design and materials, a U-cup seal can be effective in low and medium pressure applications and can accommodate worn or out-of-round service environments.

Typically manufactured from 80 durometer nitrile, making them capable of service conditions with a temperature range of -40°F to +250°F, U-cups and reinforced cup seals can also be molded using:

- Internally-lubed nitriles for low friction applications

- Fluorocarbons (FKMs) for high temperature environments (over +400°F)

- Ethylene propylenes for phosphate ester fluids

- Polyurethanes for applications requiring excellent abrasion, tear

More Hydraulic Seals / Dynamic Seals Information

Sealing Low-Compressive Loads with Multi-Swell™ Style 3760Web Seal recommends the new Multi-Swell Style 3760 gasketing material from Garlock for sealing applications with low compressive loads or where the flanges aren’t rigid enough....

Sealing Low-Compressive Loads with Multi-Swell™ Style 3760Web Seal recommends the new Multi-Swell Style 3760 gasketing material from Garlock for sealing applications with low compressive loads or where the flanges aren’t rigid enough.... ProTech™ Bearing Isolator SealsWith its unique labyrinth design, the Parker ProTech isolator seal's superior quality and high performance make it the ultimate in bearing protection. Parker, the innovation leader in bearing isolator technology, has designed this unique sealing component to deliver maximum protection for a multitude of applications. Web Seal can provide ProTech seals in many standard and custom designs....

ProTech™ Bearing Isolator SealsWith its unique labyrinth design, the Parker ProTech isolator seal's superior quality and high performance make it the ultimate in bearing protection. Parker, the innovation leader in bearing isolator technology, has designed this unique sealing component to deliver maximum protection for a multitude of applications. Web Seal can provide ProTech seals in many standard and custom designs.... Creating a Perfect Oil SealA good oil or radial shaft seal is designed to either keep oils or other fluids from leaking out of a mechanical component or to keep contaminants from finding their way in, and many times both. Pumps, mixers, motors, turbines and gear boxes in a variety of industries are susceptible to problems that can be caused by ...

Creating a Perfect Oil SealA good oil or radial shaft seal is designed to either keep oils or other fluids from leaking out of a mechanical component or to keep contaminants from finding their way in, and many times both. Pumps, mixers, motors, turbines and gear boxes in a variety of industries are susceptible to problems that can be caused by ...